https://connorconstructionllc.com/wp-content/uploads/2025/09/Connor-Construction-Industrial-Construction.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2022/03/Connor-Construction-Logo-No-Key.png

AbstraktMarketing2025-09-24 08:35:532025-10-06 16:24:53How to Plan Your Industrial Construction Project for Growth and Flexibility

https://connorconstructionllc.com/wp-content/uploads/2025/09/Connor-Construction-Industrial-Construction.jpg

1250

2000

AbstraktMarketing

/wp-content/uploads/2022/03/Connor-Construction-Logo-No-Key.png

AbstraktMarketing2025-09-24 08:35:532025-10-06 16:24:53How to Plan Your Industrial Construction Project for Growth and FlexibilityMaximizing Space Through Smart Industrial and Warehouse Design

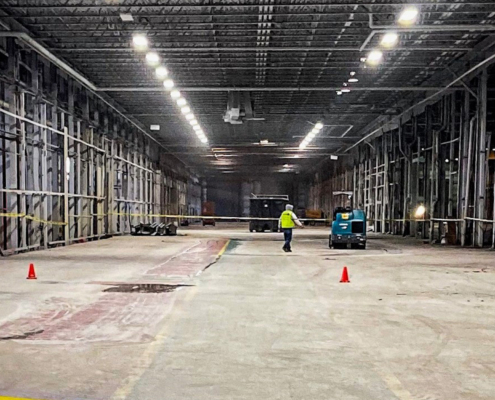

Struggling to make the most of your facility’s footprint? You’re not alone. Many industrial tenants and warehouse owners find themselves limited by inefficient layouts, outdated storage systems, or construction that didn’t account for long-term flexibility. Whether you’re planning a new build or retrofitting an existing structure, thoughtful warehouse design is the key to unlocking efficiency, productivity, and profitability.

The Hidden Costs of Poor Space Utilization

Underutilized space in warehouses and industrial buildings can impact aesthetics as well as your bottom line. Wasted square footage can lead to increased overhead, higher storage costs, limited scalability, and logistical slowdowns that disrupt operations. When your layout doesn’t serve your workflow, inefficiencies multiply.

Many facilities suffer from poor initial planning or have outgrown their original design. Over time, racking becomes chaotic, loading areas get congested, and navigating the building turns into a daily obstacle course. These pain points slow things down and hinder employee performance, customer satisfaction, and your ability to scale.

That’s where smart warehouse design, guided by experts like Connor Construction, can turn things around.

Designing for Efficiency From Day One

The best time to solve space issues is during initial construction. Smart warehouse design starts with planning for flexibility and operational flow, not just square footage. Whether you’re planning industrial construction or a warehouse ground-up build, targeted design strategies make a major difference.

Optimize Vertical Space

Don’t just build out, build up. In modern warehouse design, utilizing vertical space is one of the most effective ways to maximize square footage without expanding your footprint. Incorporating taller clear heights allows for multi-tier racking, mezzanines, and high-density storage. This approach is especially valuable in warehouse construction, where vertical volume often goes unused but can greatly increase storage capacity and operational efficiency.

Use the Right Racking Systems

Storage solutions should be tailored to the specific type, size, and turnover rate of your inventory. Implementing the right racking system, from pallet flow to cantilever or drive-in racks, ensures your warehouse design supports both efficiency and scalability. When racking is integrated into the overall facility layout from the start, you can reduce wasted space and streamline picking, packing, and replenishment processes.

Plan for Ideal Column Spacing

Column spacing may seem minor, but it significantly impacts layout flexibility and long-term productivity in industrial construction. Poorly placed columns can interfere with racking alignment, forklift navigation, and equipment movement. By planning optimal spacing early in the warehouse design process, you create a more open and navigable interior, enabling smoother logistics flow and better use of every square foot in the facility.

Design Dock and Loading Areas for Flow

The layout and orientation of loading docks directly affect how efficiently goods move in and out of your facility. Misaligned dock doors, awkward drive paths, or oversized staging areas can all lead to space inefficiencies and slower workflows. Strategic dock design, based on delivery schedules, product types, and space needs, keeps operations streamlined, minimizes turnaround times, and ensures every square foot is contributing to productivity.

Connor Construction’s team understands how to balance these elements during warehouse construction to align with your future operational needs.

Remodeling and Retrofitting for Better Space Efficiency

If you’re working with an existing warehouse or industrial facility, don’t worry: Remodeling and retrofitting can breathe new life into your space.

Modern retrofits often focus on replacing outdated layouts with more dynamic, space-saving configurations. This might include installing vertical storage systems, rearranging departments to minimize cross-traffic, or upgrading lighting and HVAC to free up ceiling room for equipment.

Connor Construction’s industrial renovation experience ensures your retrofit considers both structural limitations and operational goals, helping you maximize your existing investment without the need for a full rebuild.

Explore Connor Construction’s design and build services to discover how smart industrial and warehouse design can help you maximize every inch of space.

Smart Layout Planning: Where Design Meets Function

Even the most advanced systems can’t overcome a poor layout. The foundation of great warehouse design is strategic space planning, where movement, storage, and safety intersect seamlessly.

Optimize Traffic Flow

Efficient traffic flow is essential in warehouse design to minimize congestion, avoid accidents, and increase productivity. Design wide, clearly marked aisles that accommodate forklifts and foot traffic with ease. Separate pedestrian walkways and staging areas from heavy machinery paths. Streamlined movement through the facility reduces product handling time, prevents damage, and ensures that your team can maintain a safe and consistent workflow throughout daily operations.

Separate Storage and Processing Zones

Clearly defined zones for each function, such as receiving, picking, packing, and shipping, help prevent cross-contamination of processes and improve overall efficiency. With designated areas, teams can work without unnecessary interruptions or confusion, reducing delays and increasing order accuracy. A well-zoned warehouse design also supports better inventory management and ensures that every task has the space and tools needed for smooth execution.

Incorporate Flexible Spaces

Modern warehouse construction benefits greatly from adaptable environments. Design modular areas that can shift based on operational demands, such as expanding production lines, adding new racking, or accommodating temporary inventory surges. Flexible spaces future-proof your facility, allowing you to respond to growth, seasonal trends, or shifts in product demand without undergoing costly renovations every time your needs evolve.

Use Technology to Inform Layout

Smart systems and automation should influence your warehouse design from the start. Barcode scanners, warehouse management systems (WMS), and automated conveyors all have space and workflow implications. By integrating these technologies into the layout planning phase, you can reduce unnecessary movement, improve inventory visibility, and enhance picking and packing efficiency. This helps create a more responsive and intelligent warehouse environment.

When Connor Construction approaches warehouse design, every square foot is treated as a functional asset, not just empty floor space.

Ensure an Efficient Warehouse Design By Partnering With Connor Construction

From initial site planning to retrofitting older spaces, Connor Construction specializes in warehouse design and industrial construction that prioritize efficiency, flexibility, and future growth. Our team works closely with facility managers and business owners to solve space challenges with practical, scalable solutions.

Whether you’re expanding operations or optimizing what you already have, the right partner makes all the difference. With our expertise in warehouse construction and design strategy, Connor Construction ensures your facility is built not just for today, but for the future.